By 2025, there will be nearly 75 billion IoT devices on earth. IoT spending in every category is up and approaching more than $202 billion worldwide. There are few organizations without a plan for digital transformation and improving operations or adding new products with IoT. Those ahead of the curve are providing new services rooted in real-time IoT data. Embracing the technology is easy, but many organizations are having trouble getting IoT projects through to completion.

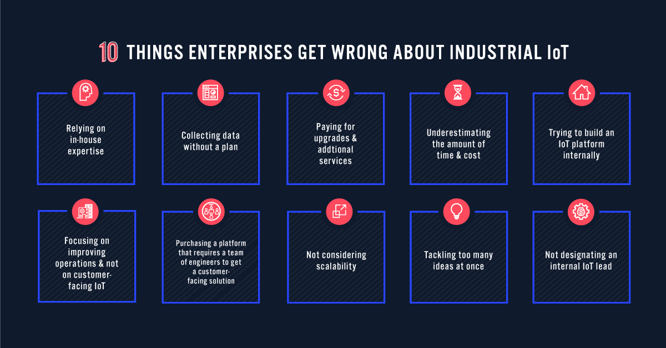

Why do industrial IoT projects fail? Some studies point to a lack of IoT leadership and expertise. It also happens when companies try to build a platform instead of buying one. Below is a list of ten other things enterprises get wrong about industrial IoT with suggestions about what to do instead.

10. Not Designating an Internal IoT Lead

In a recent McKinsey study about IoT leaders versus IoT laggards, over seventy percent of respondents agreed: an internal champion, preferably the CEO, is a vital part of an enterprise’s success with IoT. Besides an internal IoT champion -often in the C-suite or in senior leadership- an IoT project needs an internal project manager.

Because an IoT solution touches many parts of the business, management and collaboration are important. Depending on the project, a roadmap will need to be defined, a team of vendors will need to be managed, and updates will need to be shared. When the IoT project becomes an initiative, the new service will need to be supported indefinitely. Many projects start with buy-in and excitement but when a designated leader is not assigned and cannot keep up the momentum, the project suffers.

Do this instead: Build an internal IoT alliance with others whose roles will directly benefit from the solution and designate a leader with capacity. Create a clear roadmap, define success early, and integrate the development into everyone’s priorities.

9. Trying To Build an IoT Platform Internally

NetworkWorld did a study of what it might cost to build an IoT platform instead of buying a platform and shared three examples. In one example, the five-year cost to build an IoT application enablement platform for fleet management was approximately $2.67 million, whereas the cost to buy an IoT application enablement platform (AEP) from a partner was $200,500.

Despite much evidence supporting the purchase of a platform, many enterprises explore the buy vs. build debate before beginning an IoT project. If internal developers can build and maintain proprietary software or infrastructure it makes sense to assume that they will be able to build an IoT platform, right? Not exactly. Building an IoT application is a massive investment with a ton of moving pieces. It requires teams with expertise in software, hardware, database management, infrastructure, embedded systems, data analytics, and UX/UI. What’s built will also need to scale. It’s not a secret that there is a shortage of engineers with IoT expertise, so getting that in-house will account for much of the budget. Many teams try to build platforms internally and get stuck, that is why several analysts recommend partnering with IoT experts to build a solution.

Do this instead: Focus on your core business. Your company wouldn’t become a plumbing company if your facility needed a new bathroom. Partner with experts. Save time and money.

8. Underestimating the Time and Cost Required

The IoT experts at Particle said it best, “Companies that go it alone often exceed their initial timelines and find that they lack the internal expertise to keep the project up and running. Unfortunately, by the time companies realize that they need additional expertise they are usually deep into the development process, making pivoting exponentially more costly.”

Creating a realistic timeline and budget requires a thorough evaluation of the need, the problem, or the opportunity. Beginning an IoT project because of a deal on free data processing is not necessarily a good thing, especially when you don’t know how many devices will connect to your platform or what other components you will need. Even after a platform is built internally, configuration and testing will be required. Some IoT partners offer readiness assessments, an IoT proof of concept, or an IoT pilot. These tools can help determine whether IoT is the right solution for the business problem, evaluate the thoroughness of partners, and provide a better idea of what IoT production will actually cost and the amount of development needed.

Do this instead: Assess your in-house talent. Begin your project with an IoT proof of concept to work out the kinks and determine a more accurate budget and timeline for production and operation.

7. Tackling Too Many Ideas at Once

Although Industry 4.0 emerged with productivity promises behind trends of completely automated processes, enterprises soon learned that Industry 4.0 is an evolution rather than a revolution, as argued by Industry Week. Many companies cannot afford to do a rip and replace of legacy technology. Pausing production is often too disruptive to business. Instead, digital transformation with industrial IoT should start with one business unit to develop a method for success and help teams make a case for using the technology in other divisions. Trying to serve too many industries and business units worked against GE Predix, as described by Inc. Magazine.

In an article about creating data-driven companies, the Harvard Business Review also encourages enterprises not to focus on overall data-driven digital transformation, but rather to identify specific projects and business initiatives that move a company in the right direction.

Do this instead: Focus on small strategic upgrades and improvements.

6.Not Considering Scalability

Scalability is the ability for an IoT solution to adapt to changes in an environment. Most often it refers to the ability for a solution to scale up, or handle more payloads or requests when a solution grows to meet the demands of more activity or more customers. Neglecting the need for scalability can negatively impact business operations if an IoT solution is handling more data than it has been built for. For example, if an OEM built an IoT application to provide its customers with real-time machine data on a platform but did not plan for every new customer to request services and in an instant needed the platform to scale to thousands of customers, the OEM would be required to move all of the data to another platform that could handle the data without disrupting service.

Do this instead: Choose a platform with a scalable infrastructure that will not require your developers to rebuild it. Plan ahead for widespread adoption of your solution with components that work from prototyping to production.

5. Paying for Upgrades and Additional Services

An IoT solution can often be the project that moves a business’ digital transformation forward, which is why any IoT supplier you choose should have a clear product roadmap and plans for research and development that complement your organization’s goals. Any future-proof technology company will provide updates to its technology to keep up with its clients’ changing needs, but some require additional costs for upgrades and additional features. Paying for every update or additional service will significantly impact the IoT production budget and disrupt development time.

IoT platform suppliers often charge for a license to use software, and the number of messages or payloads and devices that will connect. MachNation provides access to an IoT estimation tool. However, it is important to consider the cost of suppliers’ additional services. Evaluate platforms and IoT technologies and consider all costs for current and future goals. A pilot, or small rollout, can help you avoid surprises during production.

Do this instead: Ask your suppliers about their product roadmap. Conduct a PoC and a pilot to best estimate costs.

4. Collecting Data Without a Plan

Before industrial IoT, enterprises commonly required manual processes or legacy SQL databases to get data from equipment. This process allowed only a few people with SQL knowledge to interact with the data once collected.

Industrial IoT applications today provide enterprises with the opportunity to collect data from varying systems, sensors, or machines and share it through an application or interface. When data flows into a platform, it becomes accessible for multiple departments. Once data is accessible, processes can be monitored and this information can gather insights or be fed into other enterprise systems for additional value.

Although your organization may have already had a process for collecting and storing data, if it was not intentionally tagged, stored, and organized for a specific purpose, existing data may be more difficult to access and use for decision-making.

Do this instead: Work backwards from the business problem to categorize data appropriately. Identify the future opportunities and how the data you are gathering can help in other ways, as well.

3. Purchasing a Platform That Requires a Team of Engineers To Get to a Customer-Facing Solution

There are several reasons why organizations purchase an IoT cloud platform that requires additional development. The purchasing department may have preferred to work with an approved supplier; or there may have been an offer to add on to existing software services already purchased and it simply could not be refused. Unfortunately, although cloud vendors like AWS, Azure, and Google Cloud, offer a lot of capability and integration, companies who have bought in spend a considerable amount of time engineering a complete customer-facing solution using the vendors’ catalog of separate services.

Selecting an IoT platform with IoT-specific components can simplify the development of IoT solutions and reduce the time engineers will spend configuring a solution to meet unique business needs. Even if you are in the middle of a building an IoT solution with a major cloud vendor, an AEP can still help expedite the process.

Do this instead: Evaluate partners according to your business needs. Select an application enablement platform (AEP) to simplify application development.

2. Focusing on Improving Internal Operations and Not on Customer-Facing IoT.

According to Accenture, industrial IoT (IIoT) could add $14.2 trillion to the global economy by 2030. The top drivers of IIoT growth include improved operational efficiency, improved productivity, a reduction in downtime, optimization of asset utilization, and lastly the creation of new business opportunities.

IoT is often implemented to increase efficiencies and save costs, which is frequently the case for factory floor environments and smart offices. However, while these methods help impact the bottom line, IoT champions can make a stronger case for organizational changes when proving that projects offer value to the customer. Because the implementation can be expensive, time-consuming, and disruptive, a company must rally around the bigger picture, which can include the potential for a competitive advantage with new digital services for existing customers.

Few organizations are on the cutting edge of providing customer-facing IoT solutions. Besides a clear vision, it requires an IoT platform that can provide secure multiple customer-facing applications, handle millions of devices, and categorize data.

Do this instead: Ensure your IoT projects are rooted in benefits to your customers.

1. Relying on In-House Expertise

This is an issue with multiple layers. IoT teams require individuals with expertise in infrastructure, hardware, software, connectivity, UX/UI design, data analytics, and more. Often there are gaps in internal IT teams who are in place to troubleshoot and maintain existing systems, not build new ones. Because there’s already a lack of IoT expertise to keep up with the more than 20 billion connected things, new talent with IoT experience is often difficult to obtain.

Secondly, engineers -who make ideal leaders for IoT projects- are often charged with the responsibility to lead IoT projects in global organizations. However, as a project grows, it often requires the time and attention reserved for his or her original responsibilities.

In a recent study, McKinsey found that IoT leaders classified as those achieving cost and revenue gains of at least 15 percent or more utilize IoT partner ecosystems faster and more strategically than their peers. IoT leaders also rely more on partners for the latest technology innovations instead of attempting to create them entirely on their own.

While enterprises should certainly consider in-house expertise and work with IT instead of around it, external IoT experience is invaluable. You can find value in IoT vendors that also have a partner ecosystem to support their clients’ unique needs in hardware, connectivity, or solutions.

Do this instead: Evaluate your IoT suppliers’ network to source other capable partners for your solution.

Which side of the list are you on? If you are seeking solutions for a stalled IoT project, or if your enterprise could benefit from filling in the gaps on your team with IoT expertise, take a walk through our platform with one of our Solution Architects and learn how an IoT application enablement platform could benefit you.